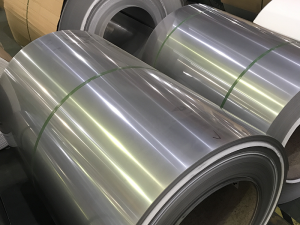

410S Stainless Steel Coil

Kufotokozera

Zofotokozera:

1.Standard: ASTM A240, JIS G4304, EN10088

2. Gulu: 200series&300series&400series

3. Makulidwe: 0.03mm - 6.0mm

4. M'lifupi: 8mm-600mm

5. Utali: monga pempho la makasitomala

6. Pamwamba: 2D, 2B, BA, Mirror yatha, N04, Hair Line, Matt finish, 6K, 8K

7.Technology: kuzizira kozizira / kuzizira kugudubuza / kutentha kotentha

Zida:

| Mtundu | Gulu | Gulu | Chemical Component% | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Zina | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | Zithunzi za SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304l pa | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309s ndi | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310s | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316l ndi | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316 ndi | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317l ndi | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Kr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Kr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410s | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Kr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420j2 | 3Kr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4 PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7 PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5 PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Zambiri zoyambira

410s Stainless Steel Coil, yokhala ndi kukana bwino kwa dzimbiri komanso machinability, ndi chitsulo chambiri komanso chitsulo chodulira.410S ndi mtundu wachitsulo womwe ukhoza kusintha kukana kwa dzimbiri ndi mawonekedwe a 410 steel.410S ndi chitsulo champhamvu kwambiri chomwe chingapititse patsogolo kukana kwa dzimbiri kwa 410 zitsulo.Amagwiritsidwa ntchito ngati masamba a turbine komanso magawo otentha kwambiri.

• Zofotokozera: AISI 410s, ASTM 410s

• Kumaliza: Ba pamwamba, 2b pamwamba, No.1 (khungu loyera), 2D pamwamba, No.4 (frosted), HL (waya kujambula), 8K pamwamba ali ndi khalidwe labwino kwambiri

• Kulekerera mphero pa makulidwe & flatness applies.Imbani JM Steel ngati mukufuna makulidwe enieni kapena malangizo ambewu.

410S Khalidwe Machining luso

1D - Pamwambapa pali mawonekedwe osasunthika, omwe amadziwikanso kuti fog surface.

Ukadaulo wokonza: kugudubuza kotentha + kuwombera kochulukira + kupukuta kozizira + kukokomeza.

2D - Mtundu woyera wasiliva pang'ono.

Ukadaulo wokonza: kugudubuza kotentha + kuwombera kochulukira + kupukuta kozizira + kukokomeza.

2B - Siliva yoyera yokhala ndi gloss bwino komanso kusalala kuposa mawonekedwe a 2D.

Ukadaulo wokonza: kugudubuza kotentha + kuwombera kuwombera kutsogola + kugudubuza kozizira + kukokomeza + kuzizimitsa ndi kupindika.

Ba - Chonyezimira bwino kwambiri, chowoneka bwino ngati galasi.

Ukadaulo wokonza: kugudubuza kotentha + kuwombera koyang'ana kutsokomola + kugudubuza kozizira + kutsogola + kupukuta pamwamba + kuzimitsa ndi kupiringizika kotentha.

No.3 -- gloss yabwino, pamwamba pa njere.

Processing luso: kupukuta ndi tempering anagubuduza kwa 2D kapena 2B ndi 100 ~ 120 abrasive zipangizo (JIS R6002).

No.4 -- Kuwala bwino, mizere yabwino pamwamba.

Processing ndondomeko: kupukuta ndi tempering anagubuduza kwa 2D kapena 2B ndi 150 ~ 180 zipangizo abrasive (JIS R6002).

HL -- Silver imvi yokhala ndi mizere yatsitsi.

Ukadaulo wokonza: Zogulitsa za 2D kapena zinthu za 2B zokhala ndi granularity yoyenera ya zida zopukutira popukuta pamwamba ndi njere yosalekeza.

MIRRO -- Zodabwitsa.

Ukadaulo wokonza: Zogulitsa za 2D kapena zinthu za 2B zokhala ndi granularity yoyenera ya zinthu zogaya zomwe zikupera ndi kupukuta mpaka pagalasi.